Co2 Laser Cutter le Engraver bakeng sa MDF/Wood/Acrylic

KOPO

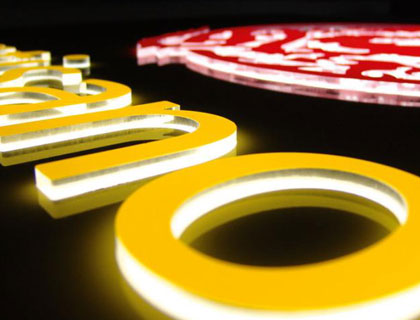

Mochini oa ho itšeha oa laser oa Co2 ke mochini o sehang o se nang tšepe oa tšepe le mochini o betlang, o loketseng acrylic, boto ea mebala e habeli, letlalo, lesela, pampiri, lebokose la ho paka ka lehong, bamboo, khetla, lenaka la tlou, rabara, 'mabole joalo-joalo.

PARAMETER

| Boholo ba ho sebetsa: 600 * 400mm/600*900mm/1300*900mm//1400*100mm/1600*1000mm | Li-tube Watts: 80W/100W/130W/150W/200W/300W |

| Mofuta oa Laser: CO2 e tiisitsoeng ea khalase e koetsoeng | Hlooho e Sehang: Motho a le mong |

| Sistimi ea Ts'ebetso: RDC6445G | Mokhanni le Motor: stepper kapa servo |

| Cooling System: Pholiso ea metsi | Ho itšeha Lebelo: 0-600mm / s |

| Lebelo la ho Feta:0-1200mm/s | Phetoho e nepahetseng: ≤± 0.01mm |

| Bonyane Bongata ba Lengolo: Senyesemane: 1mm | Software e lumellanang: CorelDraw, AutoCAD, Photoshop |

LIEKETSENG

Tafole poleiti botenya ke5mm, etsa hore mochine o tsitsitse haholoanyane, 'me o se ke oa fetoha ka mor'a lilemo tse ngata.

Ha re kenya sistimi ea terene, re sebelisa lisebelisoa tsa profeshenale tsa ho leka-lekanya ho boloka terene e le 100%, e netefatsa hore mochini o sebetsa hantle haholo.

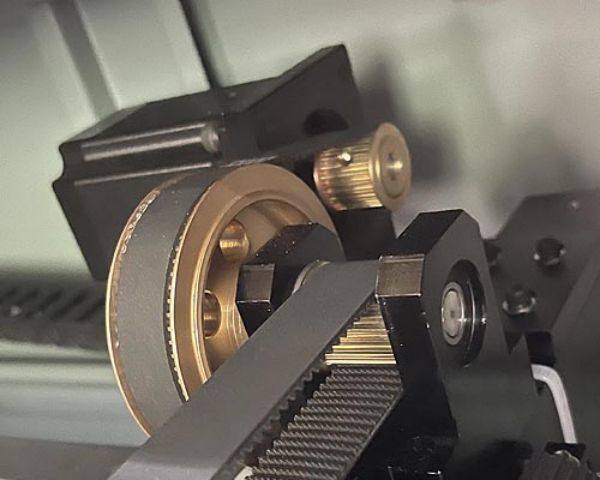

Mochini o nang le mokelikeli oa koporo, o tšoarella ho feta aluminium pully, meno a aluminium o ka sebelisoa habonolo, 'me ho nepahala ho tla theohela tlase.

Re rala poleiti ea balebeli ka ho khetheha, e ka sireletsa opereishene ho tsoa kotsi ea laser ka phoso.

LIEKETSENG

MOSEBETSI VIDEO

MAKHETHA

1. Lihlooho tse peli kapa lihlooho tse 'nè li fumaneha bakeng sa khetho ea hau, e ka sebetsa lisebelisoa tse peli kapa tse' nè tsa li-pcs ka nako e le 'ngoe ho phahamisa katleho.

2. Tafole e holimo le e tlase: e loketse thepa e teteaneng.

3. Rotary: e ntle bakeng sa botlolo, senoelo, le lisebelisoa tse ling tse tšoanang.

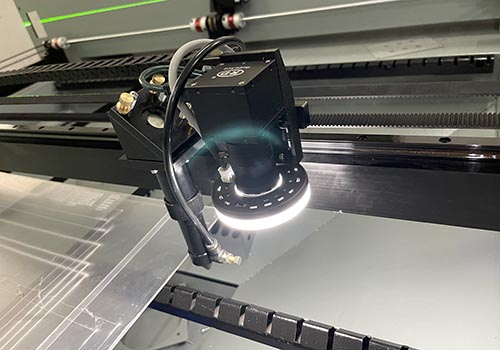

4. Khamera: ha mochine o kenya k'hamera, o ka etsa pina ea ho itšeha, joalo ka label le moralo oa ho itšeha.

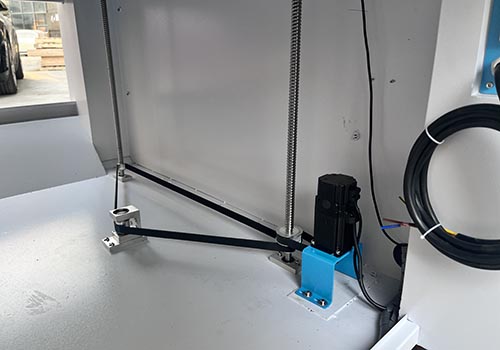

5. Sesebelisoa sa ho tsepamisa mohopolo ka ho iketsa: se ka tsepamisa maikutlo ka bohona ha botenya ba thepa bo fapane, boloka nako ea hau.

6. Setsi sa mollo: ha thepa ea ho itšeha e tukang e tšoara mollo, e tla tšosa, u ka e fumana hang-hang 'me u sebetsane le eona.

7. Leseli la pontšo: e tla bontša mochine o fapaneng oa boemo ba ho sebetsa, ho u bolella mochine o sebetsang kapa ho emisa ha u sa eme ka mochine.

8. Leseli le khubelu: sesebelisoa sena se ka u bontša boemo ba ho itšeha mochine pele mochine o qala ho khaola.

Lihlooho tse 'nè tsa ho itšeha

Tafole ya hodimo le tlase

Rotary

Khamera

Tsepamisa maikutlo ka ho iketsa

Setsi sa mollo

Leseli la sesupo

Leseli le lefubelu

KHOETSO

Re fana ka koetliso ea mahala ea tekheniki ho fihlela moreki a khona ho sebelisa lisebelisoa ka tloaelo.Likahare tsa mantlha tsa koetliso ke tse latelang:

1. Tsebo ea motheo le melao-motheo ea laser.

2. Kaho ea laser, ts'ebetso, tlhokomelo le tlhokomelo.

3. Molao-motheo oa motlakase, ts'ebetso ea tsamaiso ea CNC, tlhahlobo ea phoso e akaretsang.

4. Mokhoa oa ho itšeha oa laser.

5. Ts'ebetso le tlhokomelo ea letsatsi le letsatsi ea lisebelisoa tsa mochine.

6. Phetoho le tlhokomelo ea tsamaiso ea optical path.

7. Thuto ea tšireletso ea laser processing.