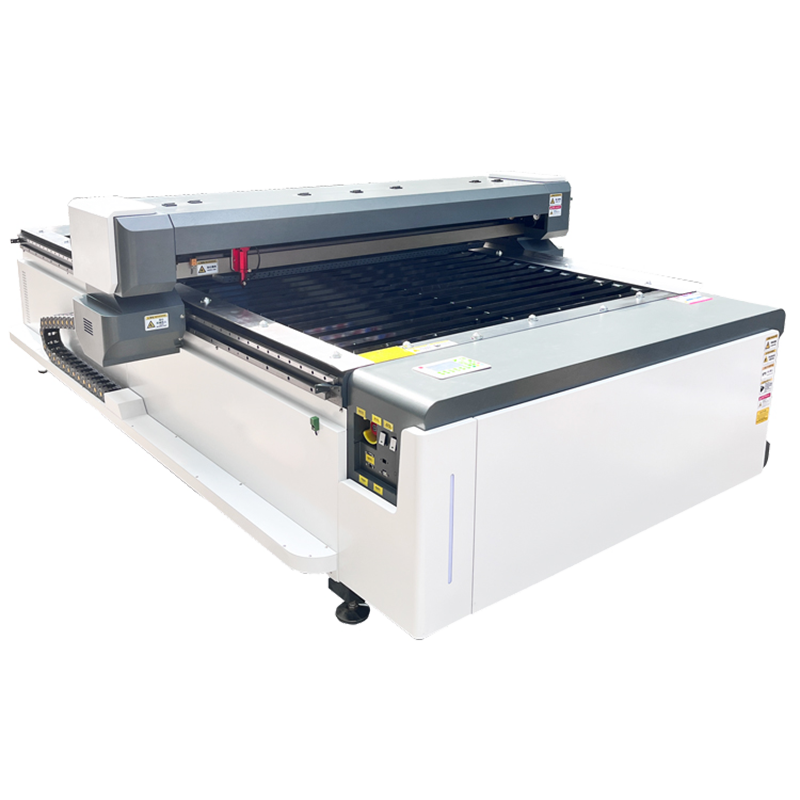

1325 1530 Mochini oa ho Seha Laser oa Non-Metal

KOPO

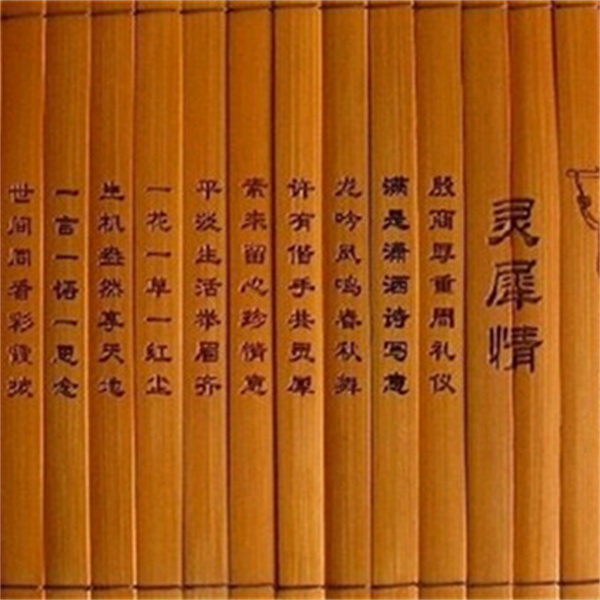

| Lintho tse bonahalang | Ho betla | Ho poma | Lintho tse bonahalang | Ho betla | Ho poma |

| Acrylic | √ | √ | MDF | √ | √ |

| Boto ea Mebala e Mebeli | √ | √ | Rabara | √ | √ |

| Lehong la Tlhaho | √ | √ | Plywood | √ | √ |

| Lesela | √ | √ | Plastiki | √ | √ |

| Bamboo | √ | √ | Letlalo | √ | √ |

| Boto ea Matte | √ | √ | Pampiri | √ | √ |

| Mylar | √ | √ | Khalase ea fiber | √ | √ |

| Tobetsa board | √ | √ | Ceramic | √ | × |

| Granite | √ | × | Mabole | √ | × |

| Khalase | √ | × | Lejoe | √ | × |

| Bakeng sa boitsebiso bo khethehileng, ka kopo netefatsa esale pele | |||||

PARAMETER

| Boholo ba Mosebetsi: 1300*2500mm/1500*3000mm | Tube: 80W/100W/130W/150W/200W/300W |

| Mofuta oa Laser: CO2 e tiisitsoeng ea khalase e koetsoeng | Sistimi ea Ts'ebetso le Software: RDC6445G RD e sebetsa V8 |

| Cooling System: Pholiso ea metsi | Mokhanni le Motor: servo |

| Ho itšeha Lebelo: 0-600mm / s | Lebelo la ho Feta:0-1200mm/s |

| Phetoho e nepahetseng: ≤± 0.01mm | Bonyane Bongata ba Lengolo: Senyesemane: 1mm |

| XY Tataiso System: Linear guide rails | Interface: Skrine sa LCD se nang le sebopeho sa USB |

LIKAROLOANA

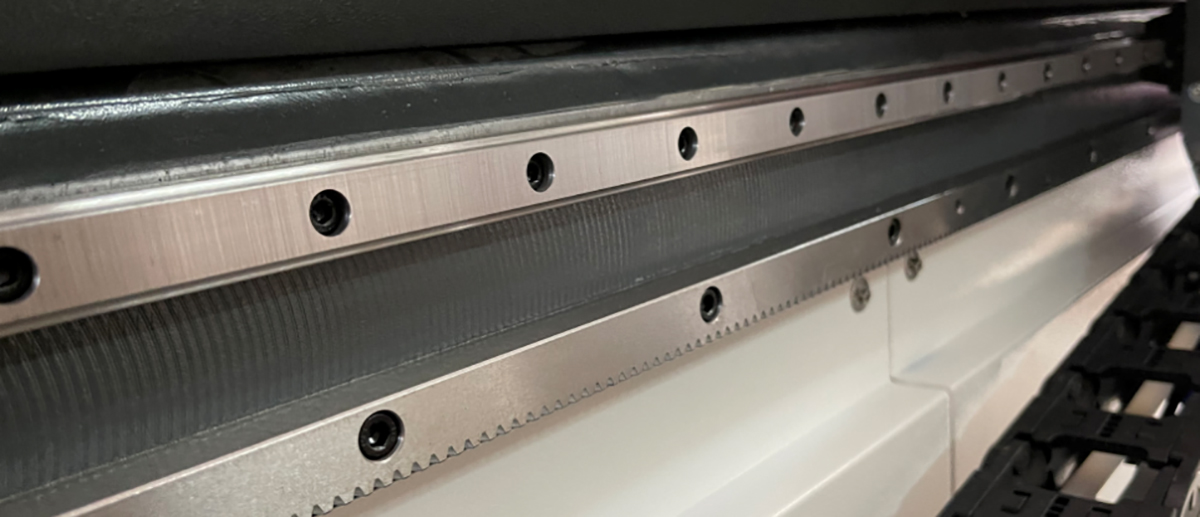

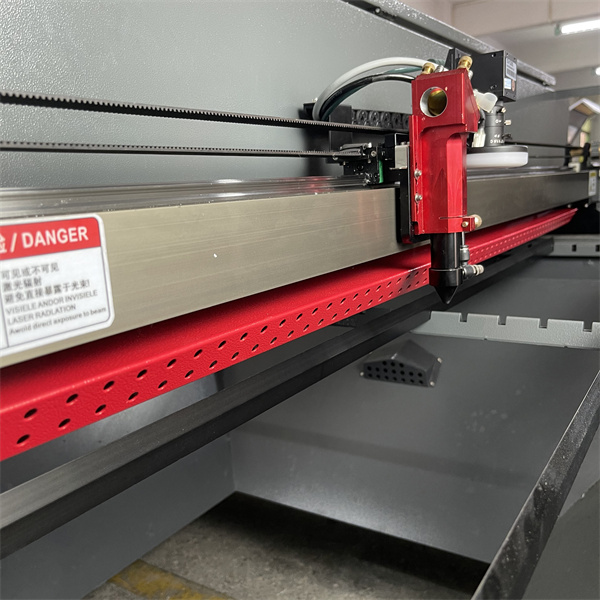

1.Precise guide rails e netefatsa ts'ebetso e nepahetseng le e se nang liphoso.Mokhoa oa bopula-maliboho o tsoelang pele, o potlakang oa ho itšeha le mokhoa o mokhuts'oane oa ts'ebetso o ntlafatsa katleho ea mosebetsi;e tsitsitse kamehla likarolo tsa phepelo ea matla a laser ho lelefatsa bophelo ba tube ea laser.

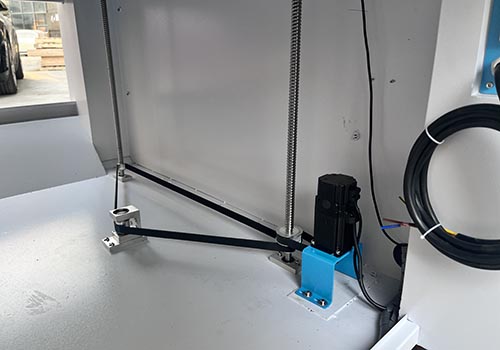

2.Ho sebelisa sebopeho sa li-triangular ka lehlakoreng la bethe, mochine o tsitsitse haholoanyane, le ho nepahala ho phahameng.

3.Bed le X-axis beam e nang le tšepe ea 6mm, 'mele oa mochine ke tšepe ea 1.5mm, e ke ke ea senyeha, e boloka ho nepahala ho phahameng ka nako e telele.

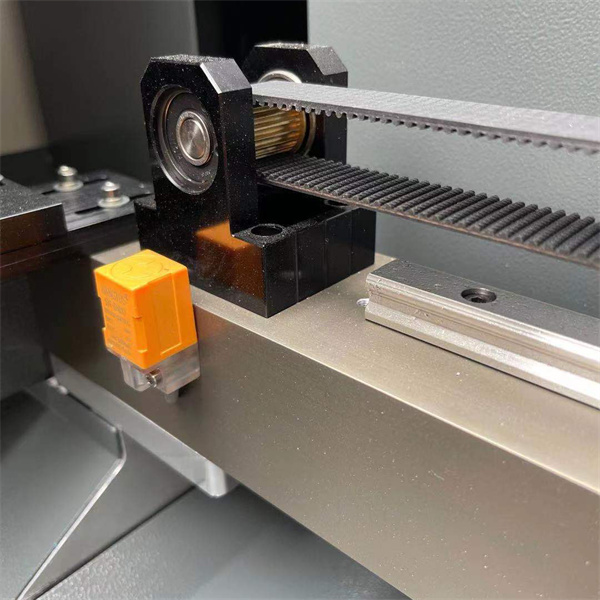

4.Racks le li-gear li na le fatše hantle, li sa sebetse ebile li nepahetse haholo.

5.Helical gear reducer ke 81π ha ba bang ba sebelisa 31π reducer, boleng bo botle haholo le ho nepahala ho phahameng.

Li-motors tsa 6.3 phase li netefatsa ho itšeha ka lebelo le phahameng le ts'ebetso e ntle.

7. ho latela mokhoa oa ho ntša mosi, o ka latelang hlooho ea ho itšeha bakeng sa mosi oa mosi

LIEKETSENG

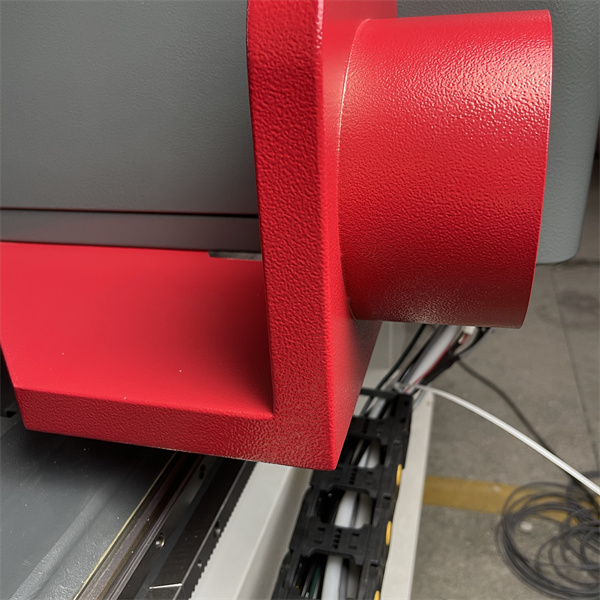

E amohela moralo oa sebopeho sa libethe tse boima, tse nyolohetseng ho tšepe e teteaneng ea 8mm le botsitso bo betere ha bo bapisoa le bethe ea mochini 'marakeng, e fihletseng boemo bo holimo indastering.

Lisebelisoa tse tharo tsa tšehetso li sa tsoa eketsoa betheng.Ka mor'a setsi sa machining milling e ntle, li-blades li behiloe holim'a mekoallo ea tšehetso ntle le phetoho ea letsoho ea ho nepahala, ho fokotsa liphoso tsa machining, ho etsa hore moralo oohle oa bethe o be o nepahetseng ho feta mechine e meng e tloaelehileng, 'me ha ho bonolo ho e senya.

Sistimi ea lisebelisoa, likarolo tsa tšepe le seporo le lisebelisoa tsa liphaephe tse tšehetsang kaofela li entsoe ke thepa ea aluminium ea mofuta oa No1, thepa e thata le e boima e tla sireletsa mochini ho tloha ho deformation, ntle le ho thothomela, ho netefatsa ho hlahisa ho nepahala ho holimo.

Li-racks le likere li fatše hantle, ha li senyehe ebile li sebetsa hantle haholo, sebaka seo seporo le rack e kentsoeng ho sona se tla siloa hantle ke setsi sa mochini ho netefatsa ho bata ka ho felletseng.

Mokhoa o bohlale oa ho latela mosi oa mosi, o ka latelang hlooho bakeng sa mosi oa mosi.

LIEKETSENG

MOSEBETSI VIDEO

MOSEBETSI VIDEO

Lihlooho tse 'nè tsa ho itšeha

Tafole ya hodimo le tlase

Rotary

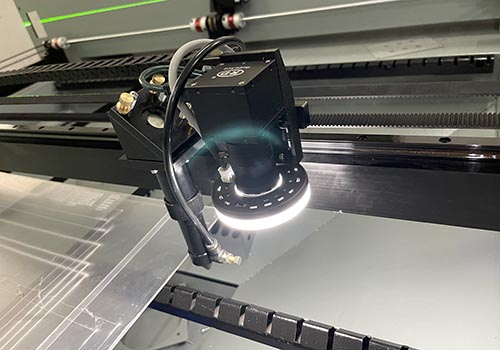

Khamera

Tsepamisa maikutlo ka ho iketsa

Setsi sa mollo

Leseli la sesupo

Leseli le lefubelu

KHOETSO

Re fana ka koetliso ea mahala ea tekheniki ho fihlela moreki a khona ho sebelisa lisebelisoa ka tloaelo.Likahare tsa mantlha tsa koetliso ke tse latelang:

1. Tsebo ea motheo le melao-motheo ea laser.

2. Kaho ea laser, ts'ebetso, tlhokomelo le tlhokomelo.

3. Molao-motheo oa motlakase, ts'ebetso ea tsamaiso ea CNC, tlhahlobo ea phoso e akaretsang.

4. Mokhoa oa ho itšeha oa laser.

5. Ts'ebetso le tlhokomelo ea letsatsi le letsatsi ea lisebelisoa tsa mochine.

6. Phetoho le tlhokomelo ea tsamaiso ea optical path.

7. Thuto ea tšireletso ea laser processing.