Ntho ea pele e lokelang ho fuoa tlhokomelo e khethehileng ke hore ha u hlahloba li-terminals tse hokahanyang ka hare kapa ka ntle ho mochine oa welding, matla a tlameha ho tima.

1. Hlahloba kamehla;mohlala, hlahloba hore na fan e pholileng e potoloha hantle ha mochine oa welding o sebetsa;ho sa tsotellehe hore na ho na le litšisinyeho tse mpe, melumo le menko;kapa khase;hore na thepa e kopantsoeng le ho koaheloa ha lithapo tsa ho tjheseletsa li hlephile kapa ho phunya;hore na lithapo tsa ho cheseletsa lia hlepha kapa lia eboha le hore na ho na le mocheso o sa tloaelehang lenonyeletsong lefe kapa lefe.

2. Ka lebaka la pholileng ea moea e qobelloang ea mochine oa welding, ho bonolo ho kenya lerōle le tsoang libakeng tse potolohileng le ho bokella ka hare ho mochine.Ka hona, re ka sebelisa moea o hloekileng le o omileng khafetsa ho tlosa lerōle mochining oa welding.Haholo-holo, likarolo tse kang li-transformer, li-reactors, likheo pakeng tsa li-coil le lisebelisoa tsa ho laola elektroniki li tlameha ho hloeka ka ho khetheha.

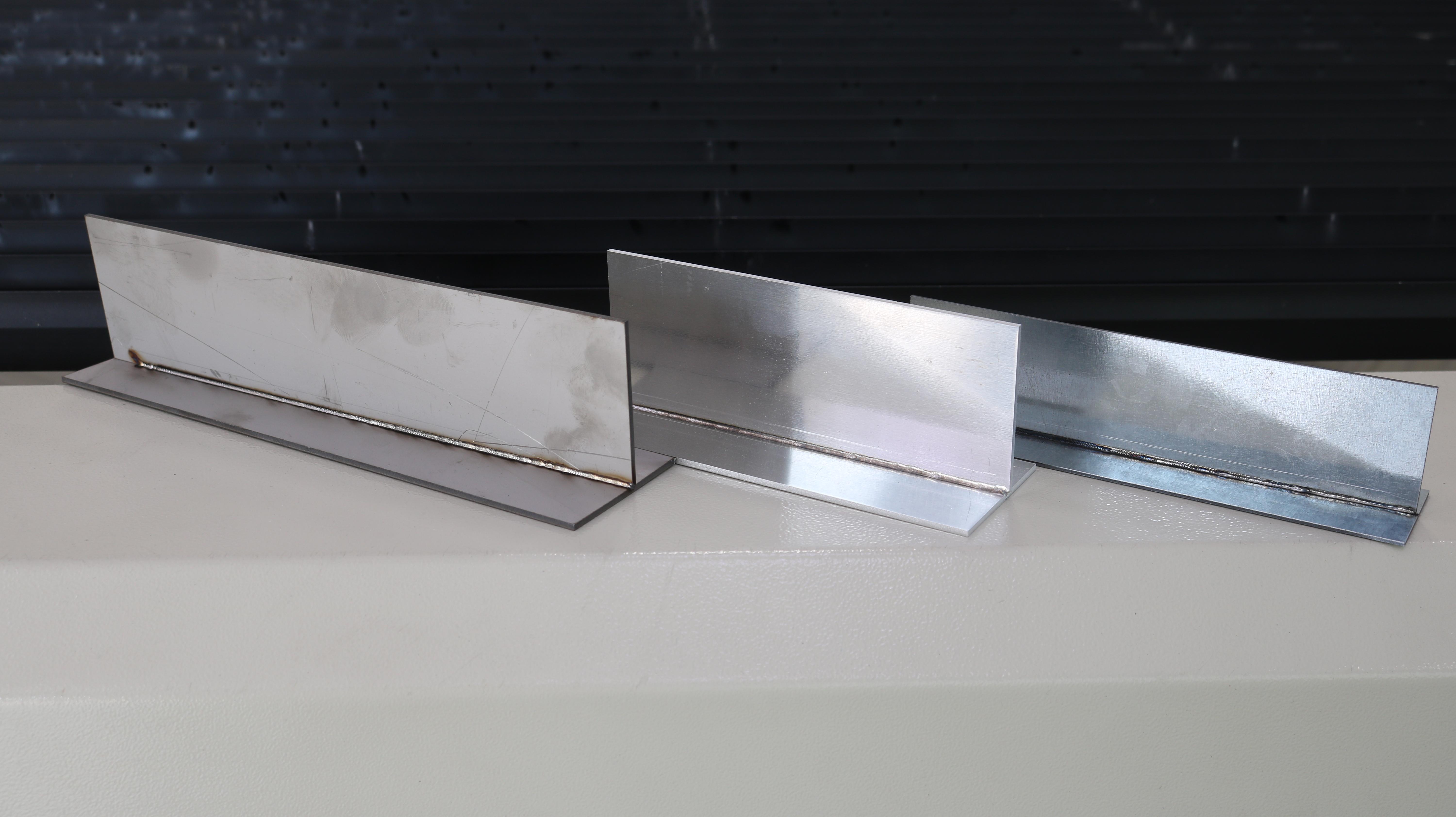

3. Kamehla hlahloba sebaka sa lithapo tsa motlakase.Sheba hore na li-screws tse lehlakoreng la ho kenya letsoho, lehlakoreng la tlhahiso, joalo-joalo, likarolo tsa lithapo tsa ka ntle, likarolo tsa lithapo tse ka hare, joalo-joalo li hlephile.Haeba ho na le mafome, e tlose 'me u netefatse hore ho na le conductivity e ntle ea ho kopana.

4. Tšebeliso ea nako e telele ea mochine oa welding ha ho pelaelo hore e tla etsa hore mokotla oa ka ntle o senyehe, o be mafome le ho senyeha ka lebaka la ho kopana, 'me likarolo tsa ka hare le tsona li tla senyeha.Ka hona, nakong ea ts'ebetso ea selemo le selemo ea tlhokomelo le tlhahlobo, ho lokisoa ka botlalo ho lokela ho etsoa, joalo ka ho nkela likarolo tse senyehileng sebaka, ho lokisa matlo le ho matlafatsa likarolo tse senyehileng.Likarolo tse nang le bokooa li ka nkeloa sebaka ke lihlahisoa tse ncha hang-hang nakong ea tlhokomelo ho netefatsa ts'ebetso ea mochini oa welding.

Tlhokomelo le tlhahlobo e boletsoeng ka holimo e ka fokotsa palo ea liphoso tsa ho tjheseletsa, tse hlokang nako le mosebetsi, empa li ka lelefatsa bophelo ba mochini oa tjheseletsa, ho ntlafatsa ts'ebetso ea ts'ebetso, ho netefatsa ts'ebetso ea mochini oa welding oa laser le ho ntlafatsa polokeho.e ke keng ea hlokomolohuoa ha ho chesetsoa.litaba tsa bohlokoa.