Moetsi oa Thekiso e Chesang ea Fiber Laser Cutter Slag Remover Cleaning 100W Handheld Laser Descaling Machine

Ka ho sebelisa mokoloto o motle oa khoebo e nyane, mofani oa thepa e ntle ka morao ho thekiso le lisebelisoa tsa sejoale-joale tsa tlhahiso, joale re fumane rekoto e ikhethang lipakeng tsa bareki ba rona lefats'eng lohle bakeng sa Moetsi oa Hot Sale Fiber Laser Cutter Slag Remover Cleaning 100W Handheld Laser Descaling Machine, Molao-motheo oa mokhatlo oa rona e tla ba ho fana ka lintho tsa boleng bo holimo, litšebeletso tse khethehileng, le puisano e tšepahalang. Amohela metsoalle eohle e haufi hore e reke liteko bakeng sa ho etsa marato a nako e telele a khoebo e nyane.

Ka ho sebelisa mokitlane o motle oa khoebo e nyane, mofani oa litšebeletso tse ntle ka mor'a thekiso le lisebelisoa tsa morao-rao tsa tlhahiso, joale re fumane tlaleho e ikhethang lipakeng tsa bareki ba rona lefats'eng lohle bakeng saChina Handheld Fiber Laser Derusting Machine le ho Tlosa Laser Cleaning Machine, Re tsepamisitse maikutlo ho faneng ka litšebeletso ho bareki ba rona e le ntho ea bohlokoa ho matlafatsa likamano tsa rona tsa nako e telele. Ho ba teng ha rona khafetsa ha lihlahisoa tsa boemo bo holimo hammoho le ts'ebeletso ea rona e ntle ea pele ho thekiso le ka mor'a thekiso ho netefatsa tlholisano e matla 'marakeng o ntseng o eketseha oa lefatše. Re ikemiselitse ho sebelisana le metsoalle ea khoebo e tsoang lapeng le kantle ho naha le ho theha bokamoso bo botle hammoho.

PARAMETER

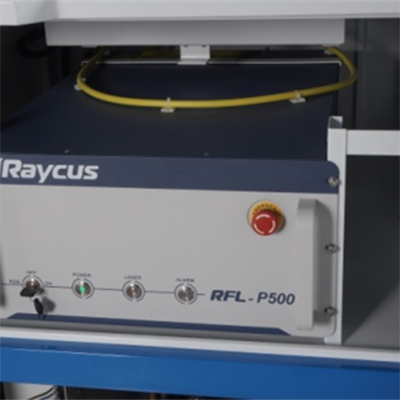

| Matla a laser | 100W / 200W / 500W |

| Mofuta oa mohloli oa laser | Raycus, IPG bakeng sa khetho |

| Laser wavelength | 1064 nm |

| Mokhoa oa ho pholisa | Pholiso ea metsi |

| Metsi a pholileng | Metsi a deionized |

| Mocheso oa metsi | 18-22 °C |

| Bophara ba skena | 10-60 limilimithara |

| Khase e thusang | Moea o hatisitsoeng/Naetrojene |

| Khatello ea moea | 0.5-0.8 MPa |

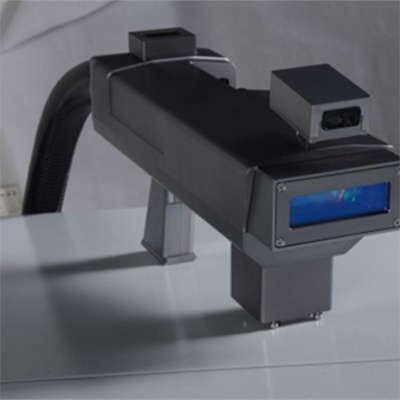

| Sesebelisoa sa boikhethelo | Handheld/ Sesebedisoa |

| Boemo ba ho sebetsa | 5-40 °C |

TŠEBELETSO

- Ho hloekisa ka laser ho nepahetseng bakeng sa boemo bo nepahetseng le boholo bo nepahetseng.

- Ts'ebetso e feto-fetohang bakeng sa likotoana tsa mosebetsi tse nang le kaho e rarahaneng ea geometri e ka bonoa ka hlooho ea ho hloekisa laser e tšoaroang ka letsoho.

- E sebelisoa haholo sebakeng se bataletseng, se kobehileng le se nang le mahlakore a mararo bakeng sa mosebetsi oa thepa ea rekere le polasetiki e nang le masoba a manyenyane haholo le a tebileng.

- Sireletsehile & tikoloho. Ntle le ho sebelisa sesepa sa lik'hemik'hale kapa lisebelisoa tse ling

- Ho hloekisa ntle le ho ikopanya le batho mme ha ho na tšenyo bakeng sa substrate E Feteletseng.

- Ho bonolo ho sebetsa, ka mokhoa o nkehang 'me e ka ba le liroboto bakeng sa ho itlhoekisa ka boiketsetso

- Ha ho tlhokomelo le lisebelisoa, ha ho na lerole, ha ho lik'hemik'hale, ha ho na tšilafalo.

- Theko e tlase ea ho hloekisa le Bokhoni bo phahameng ba ho hloekisa.

KOPO

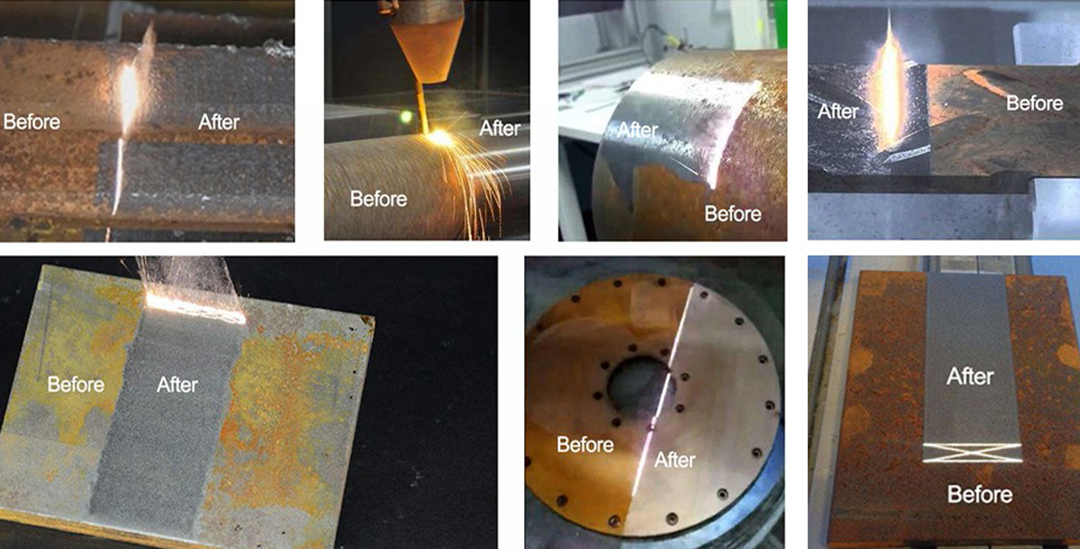

Ho tlosa mafome holim'a tšepe

Ho hloekisa ka holim'a pente

Ho hloekisa ka holim'a oli / ho hloekisa litšila

Ho hloekisa ka holim'a metsi

Welding/ Ho koaela bokahodimo pele ho kalafo

Sebopeho sa majoe holim'a lerōle le ho hloekisa lihokelo

Ho hloekisa mesaletsa ea hlobo ea polasetiki

LITŠOANTŠISO

MOLAOMOTHEO

Phapang lipakeng tsa ho hloekisoa ha laser le pulse laser:

Ka mor'a ho hloekisa leseli la pulsed, lera la pente holim'a sampuli le tlosoa ka ho feletseng, 'me bokaholimo ba sampuli bo hlaha. Metallic tšoeu, 'me hoo e ka bang ha ho na tšenyo ea sampole substrate. Ka mor'a ho hloekisa ka khanya e tsoelang pele, lesela la pente holim'a sampuli le ile la tlosoa ka ho feletseng, empa bokaholimo ba sampuli bo ne bo bonahala bo le bohlooho-botšo, 'me substrate ea sampuli e boetse e bontša micro-melting. Ka hona, tšebeliso ea khanya e tsoelang pele e ka 'na ea baka tšenyo ho substrate ho feta khanya ea pulsed.

Ka bobeli laser e tsoelang pele le pulsed laser e ka tlosa pente holim'a thepa ho finyella phello ea ho hloekisa. Tlas'a maemo a tšoanang a matla, ts'ebetso ea ho hloekisa ea pulsed lasers e phahame haholo ho feta ea lasers e tsoelang pele. Ka nako e ts'oanang, li-lasers tsa pulsed li ka laola hantle ho kenya mocheso ho thibela mocheso o feteletseng oa substrate kapa micro-melting.

Li-lasers tse tsoelang pele li na le molemo ka theko, 'me lekhalo la katleho ka li-laser tsa pulsed li ka etsoa ka ho sebelisa li-lasers tse matla a phahameng, empa khanya e tsoelang pele ea matla a phahameng e na le mocheso o moholo oa mocheso,' me tšenyo ea substrate e tla eketseha. Ka hona, ho na le phapang ea mantlha lipakeng tsa tse peli maemong a ts'ebeliso. Bakeng sa lits'ebetso tse nang le ts'ebetso e phahameng, taolo e tiileng ea ho phahama ha mocheso oa substrate, le li-substrates tse sa senyeheng, joalo ka hlobo, li-laser tsa pulsed li lokela ho khethoa. Bakeng sa meaho e meng e meholo ea tšepe, liphaephe, joalo-joalo, ka lebaka la molumo o moholo le ho chesa mocheso o potlakileng, litlhoko tsa tšenyo ea substrate ha li phahame, 'me li-lasers tse tsoelang pele li ka khethoa.

Melemo ea pulsed lasers:

Li-laser tsa pulsed li hlahisa mocheso o fokolang, ha li-laser tse tsoelang pele li hlahisa mocheso o mongata, ke ka lebaka leo li-laser tse matla a phahameng li sebelisang li-pulses. Li-laser tsa pulsed li ka etsa hore jenereithara ea laser e phomole butle-butle, athe ho hlasimolla ho sa khaotseng ho ka etsa hore laser e tsoele pele ebile e sa sitisoe. sebetsa, ho bonolo ho khutsufatsa bophelo ba jenereithara ea laser.

MOHLALA

VIDEO

Moetsi bakeng saChina Handheld Fiber Laser Derusting Machine le ho Tlosa Laser Cleaning Machine, Re tsepamisitse maikutlo ho faneng ka litšebeletso ho bareki ba rona e le ntho ea bohlokoa ho matlafatsa likamano tsa rona tsa nako e telele. Ho ba teng ha rona khafetsa ha lihlahisoa tsa boemo bo holimo hammoho le ts'ebeletso ea rona e ntle ea pele ho thekiso le ka mor'a thekiso ho netefatsa tlholisano e matla 'marakeng o ntseng o eketseha oa lefatše. Re ikemiselitse ho sebelisana le metsoalle ea khoebo e tsoang lapeng le kantle ho naha le ho theha bokamoso bo botle hammoho.